Popular in your industry

Related Searches:

Top categories

About vacuum extruder brick making machine

Vacuum Extruder Brick Making Machine: An Overview

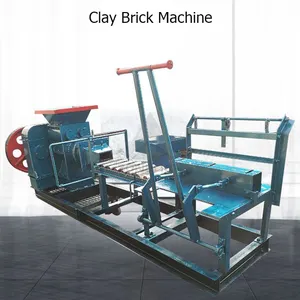

The vacuum extruder brick making machine stands as a cornerstone in the manufacturing of bricks, offering a sophisticated method for shaping clay into consistent and durable construction blocks. This category encompasses a variety of machines designed to meet the diverse needs of the brick-making industry.

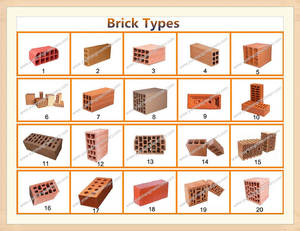

Types and Applications

Within the realm of brick manufacturing, the vacuum extruder clay brick machine is renowned for its efficiency in producing a wide array of brick types. From interlocking bricks to the more traditional solid blocks, these machines are adept at handling different materials and designs. Their versatility extends to creating paving stones, essential for constructing driveways and pathways.

Technical Specifications

A vacuum extruder brick making machine is engineered to remove air from the clay, ensuring a denser and stronger brick. When selecting a machine, it is crucial to consider the production capacity, which should align with project demands. The shape and size of the output are also pivotal factors, dictated by the molds used within the machine.

Features and Materials

The construction of a vacuum extruder brick making machine typically involves robust materials that withstand the rigors of brick production. These machines may include advanced features such as customizable molds and automated cutting systems, which streamline the brick-making process.

Advantages of Vacuum Extrusion

The use of a vacuum extruder in brick making brings several advantages, including improved consistency in brick size and density. This process also contributes to the longevity of the bricks, making them suitable for a variety of construction projects.

Complementary Equipment

In addition to the primary machinery, complementary equipment such as brick cutting devices and transport vehicles can be integrated to enhance the overall efficiency of brick production. These additions facilitate the movement of bricks from the production line to the construction site seamlessly.