Popular in your industry

Top categories

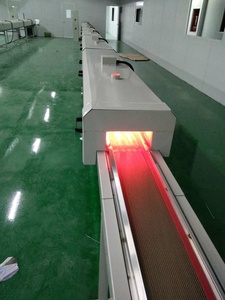

About tunnel dryer

The tunnel dryer is a specialized piece of equipment designed to accelerate the drying process by allowing products to pass through a controlled temperature and humidity environment. This type of dryer has a tunnel-like structure, with an entrance and exit for the products to move in a linear fashion. Tunnel dryers are commonly used in various industries, including food processing, pharmaceuticals, and textiles, to efficiently dry large quantities of products. They are particularly popular for their ability to provide consistent and uniform drying results, making them a valuable asset in manufacturing operations where precise drying is crucial.

Applications of tunnel dryer

The drying tunnel is widely used in the food industry for the rapid and uniform drying of food products. In the production of snacks, such as chips and extruded snacks, tunnel dryers are employed to remove moisture and achieve the desired texture and shelf life. In the baking industry, tunnel ovens serve to dry and bake various products like bread, cookies, and pastries, ensuring even and efficient baking. In the confectionery industry, tunnel dryers contribute to the drying and setting of candies, chocolates, and other sweet treats. Additionally, in the fruit and vegetable processing sector, tunnel dryers are utilized for dehydration, preserving the produce by removing moisture. The versatility of tunnel dryers makes them indispensable in the modern food processing landscape.

One specific application of tunnel dryers in the food industry is the dehydration of fruits and vegetables. These dryers are ideal for removing moisture from produce, allowing for extended shelf life without compromising taste or nutritional value. The controlled environment within the tunnel dryer ensures that fruits and vegetables are dried evenly, retaining their color, flavor, and essential nutrients. Furthermore, tunnel dryers minimize the risk of contamination and spoilage, making them a preferred choice for food manufacturers and processors.

Benefits of using tunnel dryer

A major benefit of a tunnel dryer is its ability to streamline the drying process, saving significant time and labor costs. The continuous operation of a continuous tunnel dryer allows for a consistent and uninterrupted flow of products through the drying chamber. This not only increases efficiency but also ensures a uniform drying outcome, reducing the need for manual intervention. Additionally, the controlled environment within the tunnel dryer enables precise adjustment of temperature and airflow, leading to optimized drying conditions for different types of products. This level of customization contributes to higher-quality end results and minimizes the chances of over-drying or under-drying. The scalability of tunnel dryers is another advantage, as they can be designed to accommodate varying production capacities. From small-scale operations to large industrial settings, tunnel dryers offer flexibility in meeting the drying needs of different businesses.

Another type of tunnel dryer, the screen printing tunnel dryer, is specifically designed for the curing of inks used in screen printing. These dryers feature a conveyor belt that moves the printed material through a heated tunnel, where the ink is dried or cured. This process is essential for ensuring the durability and adhesion of the ink on the substrate, whether it is fabric, paper, or other materials. Screen printing tunnel dryers are available in different configurations, including gas, electric, or infrared heating, allowing screen printers to choose the most suitable option for their specific printing requirements.