Synthetic Leather Cutting Machine: An Overview

The realm of material fabrication has been revolutionized with the advent of synthetic leather cutting machines. These sophisticated devices are engineered to cater to the diverse needs of the leather production industry, streamlining the process of cutting synthetic leather with precision and efficiency.

Types and Applications

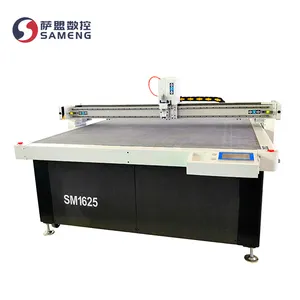

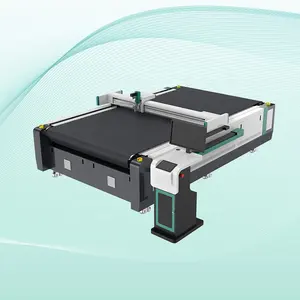

Synthetic leather cutting machines come in various configurations, each designed to fulfill specific requirements within the production line. From small-scale operations to large industrial setups, these machines serve a critical role in the manufacturing of a wide array of products, including footwear, leather bags, and office furnishings. The versatility of these machines allows for their application in multiple facets of leather processing, from initial cutting to final product assembly.

Technical Features and Materials

The construction of synthetic leather cutting machines involves robust materials that withstand the rigors of heavy usage while maintaining precision. Equipped with advanced technology, these machines offer features such as temperature and humidity control, which are essential for the varying stages of leather treatment. The ability to adjust these parameters ensures that the synthetic leather is processed under optimal conditions, enhancing the quality of the end product.

Efficiency and Sustainability

In today's eco-conscious market, efficiency and sustainability are paramount. Synthetic leather cutting machines are designed to be energy-saving, boasting low maintenance requirements. This not only reduces the operational costs but also aligns with the growing demand for environmentally friendly manufacturing practices. The machinery's efficiency is further highlighted by its multipurpose capabilities, which include pattern making, sample creation, and bulk production.

Machine Specifications and Customization

Prospective buyers can select from a spectrum of machine widths, speeds, and heat sources to find the synthetic leather cutting machine that aligns with their specific production demands. While the platform does not endorse any particular brand, it facilitates access to a comprehensive list of machine parts, accessories, and suppliers, ensuring that buyers can source the right equipment for their operations without the constraints of brand limitations.

Conclusion

The integration of a synthetic leather cutting machine into the production line can significantly enhance the efficiency of leather goods manufacturing. With a broad assortment of machines available, Alibaba.com stands as a pivotal B2B platform, connecting buyers with a plethora of suppliers and exporters, each offering machines that cater to various production scales and budgetary considerations. The platform's commitment to diversity ensures that every business can find the machinery that meets its unique production needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4