Introduction to Sandvik Cutting Tools

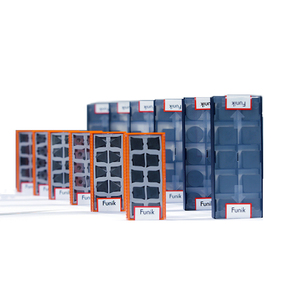

Discover the versatility and precision of Sandvik cutting tools, a comprehensive category designed for a multitude of machining operations. These tools are crafted to meet the demands of various industries, offering solutions for tasks ranging from simple cutting to complex shaping processes. The category encompasses a diverse array of tools, each engineered to facilitate specific applications with efficiency and reliability.

Types and Applications

The range of turning tools within the Sandvik collection is extensive, catering to different machining needs. Users can select from a variety of shapes and sizes, tailored for operations such as radial grooving and high-speed cutting. These tools are adept at handling materials on both big and medium-sized projects, ensuring a smooth and precise machining experience. The adaptability of grooving tools is notable, with easy adjustments for quick changes in both location and depth, streamlining the machining process.

Features and Materials

Lathe turning tools from Sandvik are recognized for their ability to maintain hardness at elevated temperatures, a critical feature for high-speed applications. The materials used in these tools are selected for their durability and thermal resistance, enabling them to perform consistently under strenuous conditions. Additionally, the woodturning lathes in this category are designed for creating symmetrical objects, showcasing the precision that can be achieved with the right equipment.

Advantages of Precision Tools

The advantages of using Sandvik's precision tools are manifold. These tools are engineered to enhance productivity by allowing for a vast range of operations such as cutting, sanding, drilling, deformation, and turning with a single setup. The ease of adjusting grooving tools contributes to minimizing downtime, facilitating a more efficient workflow. The design of these tools also simplifies the process of changing out cutters, which can be a significant time-saver during complex projects.

Selection and Usage

Selecting the right tool for your project is crucial, and the Sandvik range offers a solution for every challenge. Whether you are engaged in woodturning or metal machining, the right cutting tools can make a substantial difference in the quality of the finished product. Users can benefit from the enhanced resistance and sharpening longevity of these tools, which are key factors in achieving a professional finish on any workpiece.

Conclusion

In conclusion, the Sandvik cutting tools category on Alibaba.com presents a broad spectrum of machining solutions. These tools are not only versatile and precise but also designed with the user's need for efficiency and durability in mind. For those looking to elevate their machining capabilities, exploring this category is a step towards achieving professional-grade results in various applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4