Popular in your industry

Related Searches:

Top categories

About rice milling machine price

In the quest for food sustainability and economic efficiency, rice production stands as a critical industry. Central to this process is the rice milling machine, a technological marvel that transforms paddy into the white rice that graces dining tables worldwide. This article delves into the intricacies of rice milling machines, exploring the various types, their functionalities, and how to procure the ideal machine for your needs without breaking the bank. Whether you're a small-scale farmer or a large-scale rice producer, understanding the nuances of these machines on platforms like our B2B marketplace can significantly enhance your operation's output and quality.

Understanding Rice Milling Machines

Rice milling machines are integral in the process of converting paddy into edible rice. The objective is to produce whole white rice kernels that are free of impurities with minimal broken grains. The efficiency of milling is contingent upon the paddy quality, the milling equipment, and the operator's proficiency.

There are various types of rice milling processes. The one-step process removes husk and bran in one go, directly producing white rice from paddy. The two-step process separates husking and polishing, creating brown rice before the final white rice. More complex is the multistage process, involving several operations to convert paddy into white rice.

Different machines are used for rice milling. The traditional pestle and mortar, though labor-intensive and less efficient, are still used in remote areas. Modern mills use more sophisticated machinery, like the compact rice mill with higher capacity and efficiency, or the commercial mill that combines multiple operations for higher quality output.

The husking phase can be performed by machines such as the steel huller, which is simple and economical, or the more efficient rubber roller huller, which reduces kernel breakage. Each type of machine has its own set of advantages, such as compactness, ease of operation, and maintenance, as well as disadvantages like lower milling efficiency or potential mixing of by-products.

In selecting a rice milling machine, factors such as the type of milling process, capacity, efficiency, and the physical and chemical characteristics of the output rice are crucial. These considerations help in determining the most suitable machine for the desired quality and yield of rice.

Types of Rice Milling Machines on Our Platform

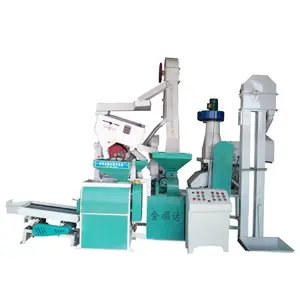

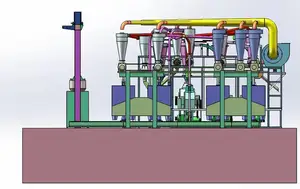

Our platform showcases a diverse range of rice milling machines catering to various scales of rice processing. The selection includes fully automatic large commercial paddy rice mill machines designed for high-volume output, ensuring efficiency in large-scale rice production. For packaging needs, machines such as rice bag packing machines, maize flour packaging machines, and vacuum packaging machines for bulk quantities are available, highlighting the platform's attention to the post-milling process.

For businesses targeting precision and smaller-scale operations, the platform offers options like the combined rice husk peeling machines, which integrate multiple functions into a single unit, optimizing space and efficiency. High-speed milling machines, such as the SB50 rice mill plant, cater to businesses prioritizing speed without compromising the quality of rice whitening. The multifunctional stainless steel rice mill machines are tailored for household use, ensuring easy operation and durability. Additionally, the site lists various combined rice milling machines, which include features like paddy husking and polishing, suitable for businesses seeking comprehensive solutions.

Our platform also provides access to specialized machinery such as the DCS automatic granule packing machine, designed for precise packaging of rice and other granular products. For larger operations, complete set rice mill machines capable of processing up to 30 tons per day offer a full-scale solution for commercial rice processing plants. These machines emphasize the balance between automation and capacity, ensuring that businesses can scale their operations effectively. The variety of machines available on our platform demonstrates the commitment to serving the diverse needs of the rice milling industry.

Key Features to Consider When Choosing a Milling Machine

When selecting a milling machine, it's crucial to consider the type and orientation of axes. Most machines operate on a 3-axis system, allowing movement along the X, Y, and Z axes, which is sufficient for a variety of operations. However, complex tasks may require 4-axis or 5-axis machines, which include rotational movements and offer greater versatility.

The spindle to table max is an essential specification, indicating the vertical distance between the spindle and the table. This determines the size of the workpiece you can accommodate. Similarly, spindle speed impacts the tooling size, feed rate, and cut depths, with higher speeds allowing for cleaner finishes and less horsepower required.

Lubrication and coolant systems are also key features, with most modern machines integrating these systems to enhance performance and longevity. Cutting fluids serve to lubricate, cool, and clear away debris, which is particularly important in CNC machines.

Lastly, power requirements are a consideration, with options between single-phase and three-phase power. Three-phase machines support larger loads and offer a more stable power supply, making them suitable for high-capacity operations, while single-phase machines may suffice for lighter, intermittent use.

The Importance of Price Point in Rice Milling Machine Selection

The cost-effectiveness of rice milling machines is a critical consideration for small and medium-sized enterprise (SME) mills. Traditional mills often face barriers to accessing modern equipment, which can lead to increased food loss. The disparity in power consumption between large commercial mills and SME mills is notable, with SME mills using approximately double the power per tonne milled. This inefficiency not only affects operational costs but also limits the ability of these mills to reinvest in better technology. Furthermore, the majority of the projected sales in the rice-milling equipment sector are expected to come from outdated machinery, which is not only less effective but also contributes to higher post-harvest losses. Modern milling technology, which can return a higher percentage of milled rice from paddy, represents a significant opportunity for SME mills to enhance their efficiency and reduce costs. By adopting newer milling solutions that lower power consumption and improve both the quantity and quality of milled rice, SME mills can transition from low-value commodity producers to value-added, market-leading food producers. This shift not only has the potential to reduce operational costs but also to contribute to food security by minimizing post-harvest losses and maximizing the return of food from existing harvests.

How to Navigate for the Best Deals

Navigating for the best deals on rice milling machines involves understanding the variety and specifications available. On the platform, you can find a diverse range of machines, from fully automatic large commercial paddy rice mill machines to smaller, household-oriented devices. For businesses looking to scale operations, high-capacity machines with features like diesel engines are listed, which are suitable for more extensive processing needs.

For those requiring precision and advanced technology, the platform offers machines with features such as color sorters, husk peeling capabilities, and high-speed milling options. These machines are designed to enhance the efficiency of rice processing, ensuring a higher quality end product. Additionally, for entrepreneurs or small-scale operations, compact and combined rice milling machines are available that can fit into smaller spaces while still providing a high level of functionality.

When searching for the right machine, consider the processing capacity, which can range from a few kilograms to several tons per day. The platform's filtering tools allow you to sort by capacity, features, and even by ready-to-ship options for quicker delivery times. It's also possible to find multifunctional machines that not only mill rice but can also handle other grains, adding versatility to your investment.

Advantages of Sourcing Milling Machines

Mini rice mills have become a pivotal component in the agricultural sector, offering a streamlined approach to rice processing. These compact units are designed for efficiency, enabling users to set up or dismantle them swiftly, ensuring that they are operational within a minimal timeframe. The variety of mini rice mills available caters to different scales of rice production, from small-scale home use to larger industrial operations. The multifunctional nature of these machines, often combining rice milling with grain grinding, adds versatility to small-scale farming operations or household use. Furthermore, the range of machines includes options that are fully automatic, promoting ease of use and consistency in rice quality. The extensive network of suppliers ensures that buyers can find a milling machine that fits their specific needs and budget, with the added convenience of ready-to-ship products for urgent requirements. The platform's global reach connects buyers with manufacturers from various regions, providing a broad spectrum of machines to compare and choose from, which can significantly enhance the rice milling process for producers.

Success Stories: Rice Producers Who Found the Right Mill

The story of the tribal farmer Gavit Parivar from Nandurbar highlights the transformative impact of the Mini Mobile Rice Mill on rural livelihoods. In regions where rice is a staple and farming the primary occupation, access to milling facilities is crucial. Before the introduction of the mobile mill, farmers in Khandbara village had to travel significant distances to process their rice, incurring extra costs and time. The establishment of a local Rice Mill not only conserved resources but also enhanced income for the community. Under the guidance of local organizations, a cooperative society was formed, enabling farmers to rent the milling equipment. This initiative empowered individuals like Ms. Tanujatai Gavit, who received training to operate the mill, thereby fostering self-employment and economic growth within the village.

Maintenance and Support for Your Milling Machine

Before operating a rice mill machine, it's crucial to perform certain preparation tasks to ensure its efficiency and longevity. This involves checking the machine's components for any signs of wear or damage and ensuring that all parts are clean and well-lubricated. Regular maintenance is key to the machine's performance, which includes inspecting belts and rollers for proper tension and condition, as well as verifying that the milling cavity is free of obstructions and the emery and iron rollers are in good shape to produce the desired rice quality.

Maintaining a rice milling plant requires a systematic approach. Daily maintenance routines should include cleaning to prevent buildup of rice husks and dust, which can affect the machine's operation and rice quality. Additionally, it's important to monitor the milling quality by checking the rice polishing rate, as this is a direct indicator of the machine's performance. By adhering to a consistent maintenance schedule, operators can help ensure that the rice mill machine continues to function at optimal levels, producing high-quality white rice with the desired precision.

Conclusion

In conclusion, the journey from paddy to plate is complex and requires the right tools for efficient and quality rice production. This article has navigated through the diverse range of rice milling machines available, highlighting the importance of understanding machine types, key features, and price points. It has also underscored the transformative effects of these machines on rice producers' operations and livelihoods, as seen in success stories like that of the Gavit Parivar. With the right maintenance and support, rice milling machines can become a cornerstone of a thriving agricultural business. By carefully considering the factors discussed, rice producers can make informed decisions that optimize their production, ensure food security, and contribute to a sustainable future in agriculture.