Popular in your industry

Related Searches:

Top categories

About low pressure injection mold machine

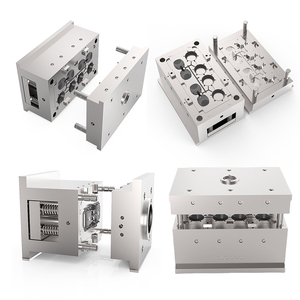

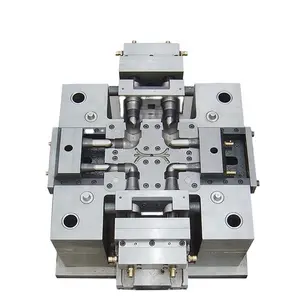

Introduction to Low Pressure Injection Mold Machines

The realm of plastic manufacturing is revolutionized by the advent of low pressure injection mold machines. These machines are pivotal in shaping plastic granules into precise dimensions, catering to a multitude of industries. The low pressure moulding machine is engineered for efficiency, ensuring a longer lifecycle and consistent performance in producing a variety of plastic components.

Types and Applications

Low pressure injection moulding machines are versatile in their applications, serving sectors from consumer electronics to the packaging industry. Their ability to create thin-walled containers, caps, and various PVC pipe fittings makes them indispensable. The adaptability of these machines allows for their use in specialized applications, including the automotive and pharmaceutical industries, highlighting their multifaceted nature.

Features and Materials

Equipped with a special screw design, the low pressure overmolding machine enhances plasticizing shot weight and speed. The construction of these machines includes a steel bush in the clamping unit, innovatively designed to minimize wear resistance. This not only extends the machine's durability but also reduces the need for frequent lubrication, indirectly cutting down operational costs.

Advantages of Low Pressure Molding

The low pressure injection mold machine boasts a single-cylinder system with a servo-valve, optimizing the response rate for high-speed operations. With clamping forces ranging from 2,000 kN to 13,000 kN, these machines demonstrate a robust resistance to external machining forces, ensuring the production of components with improved accuracy and reduced defective rates.

Specialized Design

The specialized design of the low pressure injection moulding machine aligns with the exact clamping force requirements for specific tasks. This precision ensures that resources are utilized optimally, reflecting in the quality of the end product. The machines' ability to handle different sizes of preforms further adds to their tailored approach in meeting diverse manufacturing needs.

Investing in Low Pressure Injection Molding

Choosing a low pressure injection mold machine from Alibaba's listings means selecting a tool that transforms plastic granules into products with precise dimensions. These machines are a strategic investment for businesses looking to enhance their plastic processing capabilities without compromising on efficiency or longevity.