Popular in your industry

Top categories

About forging mold

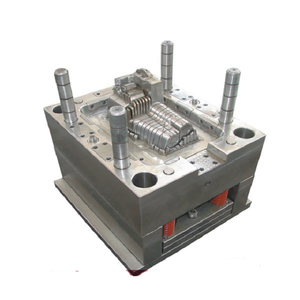

Understanding Forging Molds

Forging molds are pivotal in shaping metals and alloys into desired forms through a process known as mold forging. This technique involves the deformation of material using localized compressive forces, which is often achieved through a hammer or die. Forging molds are essential in various industries, from automotive to household appliances, due to their ability to create durable and complex shapes.

Types of Forging Molds

The diversity of forging mold types caters to different manufacturing needs. Expendable molds are suitable for single-use applications, often employed in prototyping or unique product creation. On the other hand, permanent molds boast a longer lifespan, used in repetitive, high-volume production runs. The choice of mold depends on factors such as the intricacy of design and the required durability of the end product.

Applications and Features

Forge casting molds are utilized across a spectrum of applications. In the automotive sector, they are instrumental in producing parts that must withstand extreme conditions. In the realm of custom jewelry, gold casting services employ these molds to deliver intricate designs. The common thread among these applications is the need for precision and durability, which forging molds provide. Their features include high resistance to thermal fatigue, excellent surface finish, and the ability to maintain dimensional accuracy over time.

Materials and Advantages

Materials used in forging mold production include metals like aluminum, stainless steel, and brass, each selected for their unique properties and compatibility with different manufacturing requirements. The advantages of using forging molds are manifold. They offer exceptional precision, which is crucial when creating components with tight tolerances. Additionally, the robustness of the materials ensures longevity and performance consistency of the molds.

Selection Criteria

When selecting a forging mold, it is essential to consider the material compatibility, the complexity of the item to be forged, and the expected production volume. Alibaba.com hosts a network of suppliers providing a vast array of mold options to meet diverse manufacturing needs. By analyzing product designs, suppliers can recommend the appropriate mold type, ensuring that the final product meets the required specifications without making any guarantees.

Customization and Professionalism

The plastic injection forging mold options available through Alibaba.com cater to a wide range of industries. These molds are not only sturdy but also customizable to fit specific manufacturing processes. Suppliers on the platform offer professional services to guide buyers through the selection process, ensuring that the chosen molds align with their manufacturing objectives while maintaining a professional distance and not offering direct services or guarantees.