(86 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

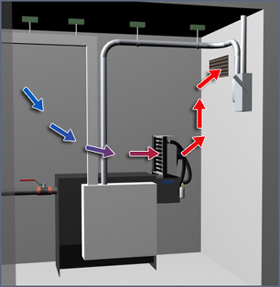

An elevator hydraulic oil cooler is a system that dissipates heat from the hydraulic oil used in the elevator's hydraulic system. The cooler is a crucial elevator component as it ensures the oil stays within the required temperature limits. This, in turn, protects the oil from overheating, maximizing its lifespan and ensuring optimal elevator performance. Several factors influence the type of oil cooler used in an elevator, including the oil pump's flow rate, the heat generated by the oil during peak elevator loading, and the prevailing environmental conditions. Below are some of the most common types of hydraulic oil coolers.

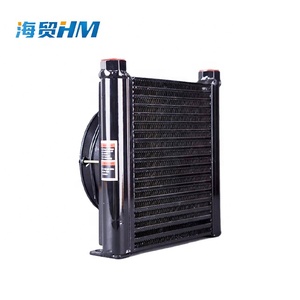

Air-Cooled

Air-cooled oil coolers use ambient air to dissipate heat from the oil. They feature a series of tubes and fins that allow the passage of the oil. Heat transfers from the oil to the cooler's surface and then to the ambient air. Natural convection or forced air generated by fans can aid the cooling process. Air-cooled oil coolers are easy to install, require minimal maintenance, and are cost-effective. However, they are affected by the prevailing weather conditions and have limited cooling capabilities.

Water-Cooled

Water-cooled oil coolers use water to cool the oil. They are designed similarly to heat exchangers, with two separate channels for the oil and cooling water. Heat transfers from the oil to the water, allowing the water to absorb the oil's heat. The water then carries the heat away, reducing the oil's temperature. Water-cooled oil coolers have a higher cooling capacity than air-cooled ones, making them suitable for applications with limited space and consistent water supply. However, they are expensive and require proper installation and maintenance.

Shell and Tube

Shell and tube coolers are a type of water-cooled cooler. They consist of a series of tubes arranged in a cylindrical shell. The hydraulic oil flows through one set of tubes, while the cooling water flows through the shell and the other tubes. This design maximizes the surface area for heat exchange, making these coolers efficient. They are widely used in industrial applications where high cooling capacity is required.

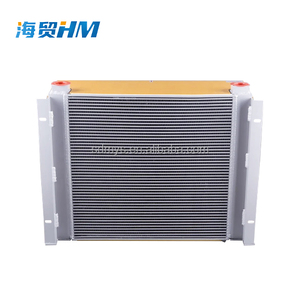

Fin and Tube

Fin and tube coolers are air-cooled coolers that use tubes with attached fins to maximize heat transfer. The cooler consists of several tubes with fins that protrude on their surfaces. The fins increase the surface area, enhancing the heat transfer from the oil to the cooler's ambient air. Natural or forced convection aids the cooling process, making these coolers suitable for applications requiring efficient cooling in compact designs.

Plate and Frame

Plate and frame coolers are also water-cooled coolers. They comprise several plates arranged in a frame, creating multiple channels for the oil and cooling water. The design maximizes the surface area for heat exchange, offering high efficiency and compactness. Plate and frame oil coolers are suitable for applications with precise temperature control requirements.

Given below are the specifications of the hydraulic oil cooler:

Hydraulic Oil Cooler Capacity

The cooler's capacity must be determined based on the heat it must eliminate, which is the rate of flow of the hydraulic oil and the temperature difference.

Pressure Drop

Pressure drop indicates the cooler's resistance to oil flow. A minimal pressure drop guarantees efficient system performance.

Material

Hydraulic oil coolers are manufactured using corrosion-resistant materials like aluminum or copper.

Heat Transfer

The heat transfer coefficient of a hydraulic oil cooler indicates its ability to transfer heat from the oil to the cooling medium (air or water).

Cooling Medium

The cooling medium is either water or air, depending on the cooler's design. For example, a water cooler requires a constant water supply, while an air cooler uses ambient air.

Temperature Control

The hydraulic oil cooler must maintain the temperature of the oil within the specified limits, ensuring effective cooling and preventing temperature fluctuations.

Oil Flow

The design of the hydraulic cooler must ensure a smooth flow of oil without unnecessary resistance or stagnation areas.

Below are some tips for maintaining the hydraulic oil cooler:

Choosing the right hydraulic oil cooler for an elevator is essential for ensuring optimal performance, reliability, and safety. Here are some critical factors to consider when selecting a hydraulic oil cooler for an elevator:

1. Capacity:

The cooler must be able to remove the heat generated by the hydraulic system. This is determined by the system's maximum flow rate and the temperature rise of the oil.

2. Size and Installation:

The cooler's size should be appropriate for the available space and the installation location's airflow and environmental conditions. Consider the installation's ease, including mounting options and the need for additional fittings or brackets.

3. Reliability and Maintenance:

Choose a cooler known for its reliability and durability. Consider the need for maintenance, such as cleaning or periodic inspections, and select a cooler that is easy to maintain.

4. Environmental Conditions:

Consider the environmental conditions where the cooler will be installed. This includes temperature extremes, humidity levels, and exposure to corrosive substances or harsh environments.

5. Noise Level:

If the cooler is installed in a noise-sensitive environment, consider the noise level it generates. Some coolers are designed to operate quietly, minimizing noise disruption.

6. Safety and Compliance:

Ensure that the cooler meets relevant safety standards and complies with industry regulations. Consider any additional safety features, such as pressure relief valves or burst-resistant construction.

7. Price and Warranty:

Consider the cost of the cooler and its overall value. Look for a warranty or satisfaction guarantee to protect your investment and provide peace of mind.

By considering these factors, one can choose the right hydraulic oil cooler for the elevator that meets the specific needs and requirements of the hydraulic system, ensuring optimal performance and reliability.

Replacing a hydraulic oil cooler is a job that can be done by a professional DIYer or a field service technician. Here is a step-by-step guide on how to replace an elevator hydraulic oil cooler.

Step 1. Choose the Right Cooler

Ensure that the new cooler to be used is the same as the old one. It should be compatible with the hydraulic system's specifications.

Step 2. Prepare the Worksite

Elevate the oil cooler to be worked on and ensure that it is well supported. Make sure that the worksite is clean and free of any debris.

Step 3. Depressurize the Hydraulic System

Before removing the oil cooler, ensure that the hydraulic system is well depressed. This can be done by following the manufacturer's procedures.

Step 4. Drain the Oil

Put a drain pan under the old oil cooler and disconnect the tubes. Allow all the oil to drain completely.

Step 5. Remove the Old Cooler

Remove the mounting bolts and take out the old cooler. Be careful not to drop any debris into the cooler during this process.

Step 6. Install the New Cooler

Mount the new cooler using bolts and follow the manufacturer's instructions. Make sure that the oil and water connections are well aligned to avoid any leaks.

Step 7. Reconnect the Hydraulic System

Make sure that all the connections to the hydraulic lines are well tightened to avoid leaks. Then, reconnect the cooler to the oil and water lines.

Step 8. Fill the System

After the cooler has been replaced, fill the system with the recommended oil as per the manufacturer's instructions.

Step 9. Bleed the System

Move the oil cooler's air out using the specified procedures. This helps to ensure that the system is well filled and that there are no leaks.

Step 10. Test the System

Run a test on the system to ensure that the cooler is working properly. Check for any leaks and make sure that the oil temperature is within the specified range.

Q1. How often should the oil cooler be cleaned?

A1. The frequency of cleaning depends on several factors, including the operating environment. A general rule is to inspect and clean the oil cooler every three months, but more frequent checks may be necessary in dirty or dusty environments.

Q2. What are the signs of a failing oil cooler?

A2. A hydraulic elevator oil cooler that is failing can show several signs like overheating of the oil, noticeable decrease in cooling efficiency, increase in noise level, and visible damage or corrosion. If the oil and cooler pipe are leaking, there can be oil residue around the cooler.

Q3. Can a small oil cooler be used for a larger elevator?

A3. No, it is not recommended. Every elevator requires a specific cooler size based on its hydraulic system's capacity. Using a smaller cooler can lead to overheating and potentially damage the elevator's hydraulic system.

Q4. Are there any alternatives to the tube and shell cooler?

A4. Yes, other designs like the plate cooler and the air/oil cooler are available. Each has its advantages and is suitable for different applications. Tube and shell coolers are popular because of their efficiency in the elevator hydraulic system.

Q5. What is the oil used in the cooler?

A5. The cooler uses hydraulic oil recommended by the system manufacturer. This oil lubricates the system components and needs cooling to maintain its properties and performance.