Introduction to Drip Irrigation Tape Production Lines

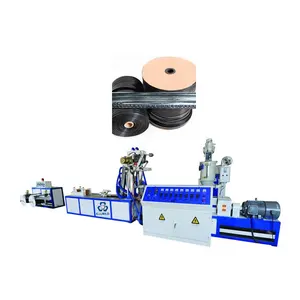

Drip irrigation tape production lines are specialized equipment designed for the efficient manufacturing of drip irrigation tape, an essential component in modern agriculture. These production lines are engineered to convert raw plastic materials into thin, durable irrigation tapes that deliver water directly to the plant roots, minimizing waste and optimizing water usage.

Types of Drip Irrigation Tape Production Machines

The machinery for producing drip irrigation tape varies, primarily categorized into single screw and double screw extruders. Single screw extruders are suitable for straightforward, less intensive production cycles, while double screw drip irrigation tape production lines are recognized for their enhanced efficiency and higher output, catering to more demanding production requirements. The choice between these types hinges on the specific needs of the production task at hand.

Applications and Features

Drip irrigation tapes, such as netafim streamline drip tape, are integral in delivering water and nutrients to crops with precision. Production lines for these tapes are versatile, capable of producing various specifications, including drip tape header line and drip line tape. These machines boast features that allow customization of tape thickness, spacing, and drip emitter intervals, ensuring that they meet diverse agricultural needs.

Materials and Advantages

Production lines handle a range of materials, including recycled plastics, contributing to sustainable manufacturing practices. The advantage of using a drip irrigation tape production line includes the ability to produce tapes like drip line repair tape, which are essential for maintaining and extending the life of irrigation systems, thereby promoting resource conservation and cost-efficiency.

Choosing the Right Production Line

Selecting the appropriate production line requires an understanding of the material compatibility and output rates. It is crucial to ensure that the machine can process the specific type of plastic intended for use and that its production capacity aligns with operational demands. Prospective buyers should consider the technical specifications and performance features of the irrigation tape drip line machinery to ensure it meets their production goals.

Conclusion

Investing in a drip irrigation tape production line is a strategic decision that can lead to enhanced efficiency in agricultural practices. With a variety of machines available, each designed to meet different production scales and requirements, buyers can find the right equipment to support their irrigation tape manufacturing needs without compromising on sustainability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4