Introduction to Cotton Dust Machines

Cotton dust machines are integral components in the textile industry, designed to enhance the quality and efficiency of cotton processing. These machines play a crucial role in various stages of cotton production, from initial cleaning to final packaging. The technology behind cotton dust machines has evolved to meet the industry's growing demands for precision and environmental considerations.

Types and Applications

There are several types of cotton dust machines, each serving a specific function within the textile sector. These include carding machines, which align cotton fibers, and textile raw material machines that process raw cotton. Their applications span across manufacturing plants, garment shops, and even extend to home use for small-scale productions. The versatility of these machines allows for a broad range of textile processing tasks.

Features and Materials

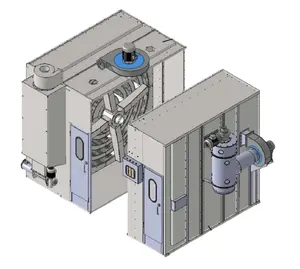

Cotton dust machines are constructed with a focus on durability and performance. Common materials used in their construction include robust metals and composites that withstand the rigors of continuous operation. Features may include advanced motor systems, programmable logic controllers (PLCs), and precise gearing mechanisms, all of which contribute to the machine's overall efficiency and reliability.

Advantages of Modern Cotton Dust Machines

Modern cotton dust machines offer numerous advantages, such as improved fiber quality and enhanced environmental controls that minimize cotton waste. These machines are designed to be user-friendly, with some models boasting features that allow for easy maintenance and operation. The emphasis on recyclability and efficient machine design reflects the industry's commitment to sustainability.

Selection Criteria

When selecting a cotton dust machine, potential buyers should consider factors such as the machine's capacity, compatibility with existing production lines, and the specific needs of their operation. It's important to choose a machine that aligns with the intended application and production volume to ensure optimal performance and cost-efficiency.

Global Availability

The availability of cotton dust machines spans across various countries, including Indonesia, India, and Egypt, reflecting the global nature of the textile industry. This wide distribution ensures that buyers can source machines that meet their regional requirements and standards, facilitating a smoother integration into their operations.

cotton dust machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4