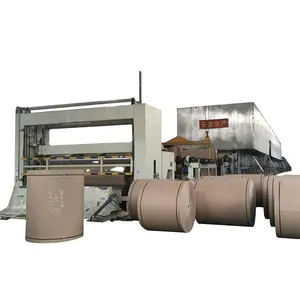

Introduction to Corrugating Medium Paper Machines

The corrugating medium paper machine is an essential component in the packaging industry, designed to produce corrugated medium paper, also known as fluting paper. This paper is a central layer of corrugated board, providing strength and durability to boxes and packaging materials. The machine's role in creating this intermediary product is crucial for manufacturers who require reliable and efficient production capabilities.

Types and Specifications

There are various types of corrugating medium paper machines to cater to different production needs. From compact models suitable for smaller operations to larger, industrial-grade machines, each offers unique specifications. Smaller units might have a production capacity of 70 to 80 pieces per minute and typically require a power input of around 3kw or more. The size and scale of the machine directly influence its output, with larger machines boasting higher capacities.

Operational Features

Modern corrugating medium paper machines are equipped with advanced features to enhance operation and efficiency. Many machines incorporate automated systems, including automatic oil lubrication, which ensures smooth running and longevity of the machine parts. Photoelectric technology is commonly used to monitor the machine's performance, alerting operators to paper shortages or operational issues, thus facilitating timely interventions.

Driving Systems and Automation

The driving mechanism of a corrugating medium paper machine can be either gear-driven or chain-driven, each offering distinct advantages in terms of maintenance and performance. Automation is a standard feature in most models, reducing the need for manual intervention and enabling a more streamlined production process. This automation extends to various aspects of operation, from paper feeding to adjustments during production.

Environmental Considerations

Sustainability is a growing concern in the packaging industry, and corrugating medium paper machines play a part in addressing this issue. The machines are capable of processing a range of paper weights and types, allowing for the production of eco-friendly packaging solutions. Manufacturers can produce corrugated medium paper that is not only strong and versatile but also recyclable, aligning with environmental standards and consumer expectations.

Applications and Versatility

The output of corrugating medium paper machines is integral to various packaging applications. From small decorative boxes to large storage solutions, the corrugated medium paper produced is customizable to fit a wide array of uses. Its versatility is evident in the range of colors, finishes, and structural designs it can support, making it a go-to material for businesses looking to package their products effectively.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4