Popular in your industry

Top categories

About coconut shell kiln

Introduction to Coconut Shell Kiln Technology

The coconut shell kiln is a specialized apparatus designed for the conversion of coconut shells and other biomass materials into charcoal through a process known as carbonization. This technology is an integral component for industries aiming to utilize organic waste efficiently and sustainably.

Design and Operation

Coconut shell kilns are engineered with simplicity in mind, ensuring ease of operation. The design of these kilns allows for the thermal decomposition of biomass without the presence of oxygen, resulting in the production of charcoal. The operational efficiency of these kilns is a key consideration, as they are crafted to process various forms of biomass, including wood, bamboo, and, predominantly, coconut shells.

Applications and Versatility

Beyond charcoal production, the versatility of a coconut shell kiln extends to the creation of activated carbon, commonly used in water filtration systems. The adaptability of these kilns to various biomass forms makes them a valuable asset in reducing waste by transforming it into usable products.

Environmental Impact and Efficiency

The environmental aspect of the coconut shell kiln is noteworthy, with certain models designed to repurpose the smoke emitted during carbonization. This feature not only enhances fuel efficiency but also aligns with eco-friendly practices by minimizing the carbon footprint of the operation.

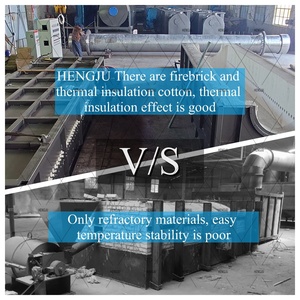

Construction and Durability

The construction of coconut shell kilns focuses on durability and minimal maintenance requirements. These kilns are typically large, horizontal structures that are installed outdoors, designed to withstand various working pressures and capacities to meet the demands of different production facilities.

Choosing the Right Kiln

Selecting the appropriate coconut shell kiln involves considering the specific needs of a production plant, including size and capacity. The right kiln can streamline the charcoal production process, making it more efficient and less labor-intensive, thereby optimizing operational workflows.