Popular in your industry

Related Searches:

Top categories

About build a vibrating table

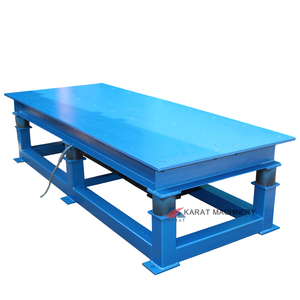

Introduction to Vibrating Tables

Vibrating tables are essential tools in various industrial processes, particularly in the construction sector. A build a vibrating table is designed to compact materials, ensuring a solid and void-free foundation for numerous applications. These tables are crucial for achieving the desired density and strength in materials such as concrete, by emitting consistent vibrations throughout the substance.

Types of Vibrating Tables

The market offers a diverse range of vibrating tables, each tailored to meet specific industrial needs. The common types include flat-top vibrating tables for general compaction tasks and grid-top tables designed for roller conveyor systems. Users can also find portable vibrating tables for fieldwork and smaller tasks, ensuring versatility across various settings.

Applications and Features

Build a vibrating table finds its applications across multiple industries, from construction to laboratory research. They are instrumental in compacting concrete, reducing air gaps, and enhancing material strength. Features of these tables include adjustable frequency and amplitude settings, which allow for customization according to material and compaction requirements. Additionally, industrial vibrating tables are equipped with robust platforms to handle heavy-duty use and ensure longevity.

Materials and Advantages

Constructed from durable metals and supported by steel springs, vibrating tables are built to withstand the rigors of industrial use. The advantages of using a build a vibrating table include improved material quality, elimination of air bubbles, and a more uniform surface finish. This results in stronger, more reliable end products, which is crucial for structural integrity and safety.

Choosing the Right Vibrating Table

Selecting the appropriate vibrating table involves considering the material type, desired compaction level, and workspace constraints. For instance, laboratory vibrating tables are ideal for precision work in controlled environments, while larger construction projects may require heavy-duty vibrating tables. It is important to assess the specific needs of the task at hand to ensure optimal performance and results.

Ensuring Quality and Safety

While exploring options for a build a vibrating table, it is crucial to focus on the equipment's ability to deliver consistent performance without compromising safety. These tables play a pivotal role in ensuring that structures can withstand natural forces and everyday wear and tear, making the selection of a reliable table an important decision.