Bottle Preform Mould Manufacturer 50cl Neck 28mm 32 Cavitiies Plastic Injection Mould For Pure Water Bottle PET Preform

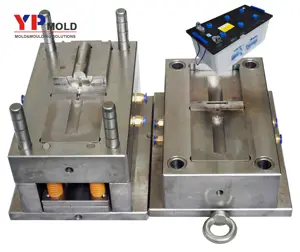

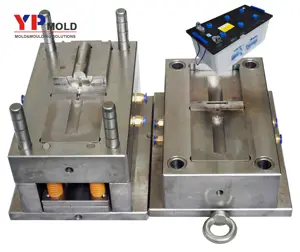

Custom Mould Design Service Outdoor Battery Box Case Injection Moulding Maker Mould For Energy Storage Battery

The realm of industrial manufacturing is vast, and within it, the battery container mould plays a pivotal role. This specialized form of mould is designed for the precise creation of battery containers, which are essential components in various electronic devices. The battery container not only houses the battery cells but also ensures their safety and connectivity within the device.

There are several types of moulds for battery containers, each tailored to different battery sizes and specifications. From small-scale consumer electronics to large industrial power systems, the application of these moulds is extensive. The design intricacies of these moulds cater to the specific needs of the battery they are meant to encase, whether it's for a slim smartphone battery or a robust automotive power source.

The materials used in battery mould manufacturing are chosen for their durability and precision. Commonly, iron is utilized for its robustness; however, other composites can be employed based on the requirements of thermal resistance and electrical insulation. Features such as corrosion resistance and ease of release are critical, ensuring the longevity of the mould and the quality of the battery containers produced.

Opting for a specialized injection mould for battery containers brings several advantages. These moulds are engineered to produce containers with high dimensional accuracy, which is crucial for battery performance and safety. Additionally, the repeatability of the process ensures consistent quality across large production runs, a key factor for manufacturers aiming to maintain product reliability.

Customization plays a significant role in the production of battery container moulds. Suppliers on Alibaba.com can tailor these moulds to specific design requirements, ensuring that the final product aligns with the client's needs. Adaptability is also a consideration; standardized features such as lift bars and clamp slots can be incorporated to streamline the manufacturing process across various mould designs.

Selecting the appropriate mould for battery casing involves considering the design, material, and specific manufacturing requirements. Suppliers on Alibaba.com can assist in this process, providing expertise to ensure that the mould selected will meet the precise needs of the production line without compromising on the quality of the battery containers produced.