Introduction to Basket Mill for Paint

The industrial basket mill is a vital piece of equipment in the paint production industry, designed to enhance the efficiency and quality of paint manufacturing. A basket mill for paint is engineered to mix, disperse, and grind pigments and additives into a consistent liquid medium, crucial for producing a wide range of paint types.

Types and Applications

Basket mills are versatile, with various models catering to different viscosity levels and production requirements. The paint grinding basket mill is particularly well-suited for processing high-viscosity paint, ensuring a smooth and homogenous product. Its applications span across the creation of emulsions, architectural coatings, and automotive paints, highlighting its adaptability in the paint industry.

Features and Materials

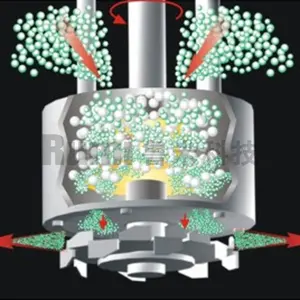

A paint dispersion basket mill typically features a stainless steel construction, offering durability and resistance to the corrosive nature of paint constituents. The design includes a grinding chamber with a rotating basket filled with grinding media, which, when combined with a shearing and impacting force, ensures efficient particle size reduction.

Advantages of Using Basket Mills

The high-speed basket mill for paint provides several advantages, including a streamlined production process that allows for quick color changes and reduced waste. The efficiency of a laboratory basket mill is evident in its ability to produce fine dispersions and its ease of cleaning, which is essential for maintaining product quality.

Environmental Considerations

Modern basket mills are designed with environmental considerations in mind. The energy-efficient basket mill reduces power consumption, while the closed system of operation minimizes solvent emissions, contributing to a safer and more sustainable production environment.

Choosing the Right Basket Mill

Selecting the appropriate paint processing basket mill involves considering the specific requirements of the paint formulation and production volume. It is essential to choose a machine that can handle the particular characteristics of the paint, such as viscosity and particle size distribution, to ensure a high-quality finish.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4