Popular in your industry

Related Searches:

Top categories

About amplifier heatsink

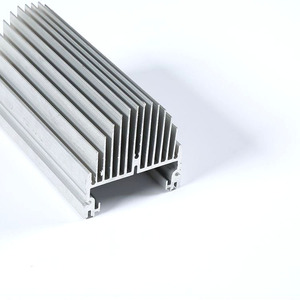

Understanding Amplifier Heatsinks

An amplifier heatsink is an essential component in managing the thermal performance of electronic devices. It serves to dissipate heat away from the amplifier's circuitry, ensuring stability and extending the lifespan of the device. This introduction explores the various aspects of amplifier heatsinks, catering to a range of applications from construction to automotive parts.

Types and Shapes of Amplifier Heatsinks

Amplifier heatsinks come in diverse shapes to accommodate different design requirements. Common profiles include L-angled, square, and T-shaped bars, each serving a unique purpose in thermal management. Solid round tubes and hollow tubes are preferred for their ease of integration, while J caps and Z clips are specialized for secure mounting. Channels and sliding track systems are also available, offering versatility in assembly and installation.

Materials and Surface Treatments

The majority of amplifier heatsinks are crafted from aluminum alloys, particularly the 6000 series, known for its excellent thermal conductivity and mechanical properties. The temper of these alloys typically ranges from T3 to T8, indicating the level of hardness and strength. Surface treatments such as powder coating, anodizing, and sandblasting are applied to enhance corrosion resistance and aesthetic appeal. For instance, anodizing adds a protective layer and can introduce various colors, while wood printing can impart a natural wood texture, ideal for decorative purposes.

Features and Customization

Customization is a key feature of amplifier heatsinks, with specifications such as thickness, ranging from 0.2mm to 20mm, tailored to meet precise requirements. Surface treatments can be selected based on the intended application, whether it's for a matte finish in lighting fixtures or a polished look in interior designs. The adaptability of these components allows for a wide range of applications, ensuring that the heatsink not only performs its function but also complements the design where it is used.

Applications and Advantages

The application of amplifier heatsinks is vast, spanning across various industries. In construction, they are integral to the thermal management of lighting systems, while in the automotive sector, they play a crucial role in keeping electronic components at optimal temperatures. The advantages of using a well-designed heatsink include improved efficiency, reduced risk of overheating, and the potential for enhanced performance of the amplifier.

Selecting the Right Amplifier Heatsink

Choosing the right amplifier heatsink involves considering the thermal requirements of your application, the environmental conditions, and the desired aesthetics. With a multitude of options available, it is important to assess the features such as material, shape, and surface treatment to ensure the heatsink meets the specific needs of your project.