What are Carding Machines

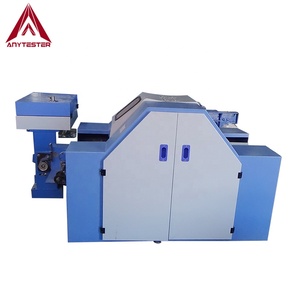

Carding machines are specialized textile machinery designed for the processing of various fibers such as cotton, wool, and synthetic materials. These machines are crucial in the early stages of textile manufacturing, where they are used to disentangle, clean, and intermix fibers to produce a continuous web or sliver suitable for subsequent processing. The primary users of carding machines include manufacturing plants, textile industries, and garment shops that require refined fibers as a precursor to spinning and fabric production.

The principle of operation for a carding machine is relatively straightforward, yet technically complex. It involves the mechanical process of individualizing the fibers, removing impurities such as dirt and short fibers, and aligning the longer fibers to create a uniform blend. The central element of a carding machine is the large cylinder or drum covered with fine wire pins that work against a series of smaller rollers and stationary flats, also covered with wire pins or card clothing. As the raw material passes through these components, the interaction between the moving and fixed elements opens up the fiber tufts, aligns them into a more orderly state, and forms them into a continuous web or sliver.

One key aspect of carding machines is their adaptability to handle different types of fibers. They can be adjusted for varying degrees of fineness and density based on the fiber characteristics and the desired end product. This flexibility makes them an indispensable tool in the textile industry. Additionally, modern carding machines often come equipped with advanced features like automatic control systems to ensure consistent quality and to optimize production efficiency.

Types of Carding Machines

In the textile industry, there are several types of carding machines tailored for various applications:

Cylinder Card: Cylinder cards are among the most common carding machines used in the industry. They consist of a large central cylinder surrounded by smaller rollers or flats that work in conjunction to open up fiber clumps and remove impurities. This type is typically used for high-volume production in textile mills.

Roller Top Card: Roller top cards feature a different configuration where roller tops are used in place of flats against the main cylinder. They offer precise control over carding intensity and are suitable for special applications where fiber damage needs to be minimized.

Revolver Card: Revolver cards have multiple small cylinders or "revolvers" that work in unison with a central cylinder. This design is known for its efficient blending capabilities and is often utilized when uniformity across large batches of fiber is paramount.

Aerodynamic Card: Utilizing air currents to separate and align fibers, aerodynamic cards are less reliant on mechanical contact, which reduces fiber strain. They are particularly beneficial when working with delicate synthetic fibers or nonwovens.

Miniature Card: For niche markets or educational purposes, miniature cards offer scaled-down functionality. They can be used for small-scale production or testing purposes within research facilities or design studios.

Each type serves specific industrial needs based on fiber properties, desired output characteristics, and production scale.

How to choose Carding Machines

Selecting the right carding machine requires careful consideration of several factors:

Fiber Type: Understanding the characteristics of the fiber you intend to process is crucial. Different fibers may require specific carding elements or settings to achieve optimal results without damaging the material.

Production Volume: Assess your expected production volume. High-volume facilities will benefit from machines that offer speed and automation features to maintain efficiency without compromising quality.

End Product Requirements: Consider what qualities your end product should have. Finer textiles may need more delicate carding action while coarser materials might tolerate more robust processing.

Machine Features: Modern carding machines come with various features such as automatic control systems that can enhance productivity and ensure consistent output quality. Evaluate these options against your operational needs.

After-sales Service: Reliable after-sales support including online support, video technical assistance, and field maintenance should factor into your decision-making process especially if operating in regions where local service may not be readily available.

By evaluating these key considerations in conjunction with your business objectives and operational capabilities, you can make an informed decision when choosing carding machines suitable for your enterprise.

Best Carding Machines on Alibaba.com

Alibaba.com stands out as a global marketplace connecting buyers with a vast network of suppliers offering an extensive selection of carding machines suitable for various industries. By facilitating connections between businesses across borders, Alibaba.com streamlines the procurement process for enterprises looking to enhance their textile production capabilities. Whether you represent a large-scale manufacturing plant seeking state-of-the-art machinery or a small garment shop aiming to expand its operations, Alibaba.com provides access to equipment that meets diverse requirements without sacrificing quality or efficiency.

With intuitive search functions and detailed product descriptions, customers can easily find machinery that aligns with their specific needs—from automatic high-speed models enhancing productivity to more straightforward designs known for their long service life. Moreover, Alibaba.com prioritizes transaction security through services like Trade Assurance which protects payments until delivery is confirmed, instilling confidence in buyers regardless of their location in over 190 countries served by the platform.

As part of its commitment to helping small and medium-sized businesses flourish globally, Alibaba.com not only offers an array of machinery but also supports buyers through comprehensive after-sales services provided by suppliers who understand the importance of maintaining equipment performance over time. By choosing Alibaba.com for your carding machine procurement needs, you can expect a seamless shopping experience backed by reliable customer support aimed at fostering long-term business growth.

Common FAQs for Carding Machines

What are the primary functions of a carding machine?

A carding machine's main functions include disentangling, cleaning, and intermixing fibers to create a continuous web or sliver, which is essential for the spinning process in textile manufacturing.

How does fiber type affect the choice of a carding machine?

Different fibers have unique properties that necessitate specific carding elements or machine settings to ensure optimal processing without damaging the material.

What are the key differences between cylinder card and roller top card machines?

Cylinder cards use a large central cylinder with surrounding rollers or flats for fiber processing, whereas roller top cards employ roller tops in place of flats, offering precise control over carding intensity.

How do production volumes impact the selection of carding machines?

Higher production volumes require carding machines that can operate efficiently at scale, often featuring automation and high-speed capabilities to maintain consistent quality.

Can carding machines handle both natural and synthetic fibers?

Yes, modern carding machines are designed to handle a variety of fibers, including both natural (like cotton and wool) and synthetic materials, by adjusting the machine settings accordingly.

What should be considered regarding after-sales service when purchasing a carding machine?

Buyers should seek reliable after-sales support that includes online assistance, video technical support, and field maintenance services to ensure the longevity and performance of their machinery.

Are there any specific features to look for in modern carding machines?

Features such as automatic control systems, enhanced safety levels, and user-friendly interfaces are valuable additions to modern carding machines that can improve productivity and quality control.

How does Alibaba.com ensure the quality of carding machines sold on its platform?

While Alibaba.com connects buyers with suppliers, it encourages suppliers to provide comprehensive product details and supports buyer protection through services like Trade Assurance.

What types of businesses can benefit from purchasing carding machines on Alibaba.com?

Manufacturing plants, textile factories, garment shops, and other businesses involved in fiber processing can benefit from the wide range of carding machines available on Alibaba.com.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4