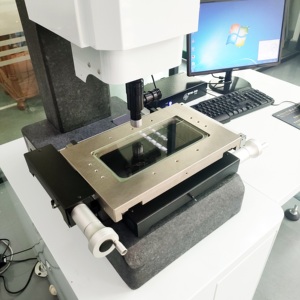

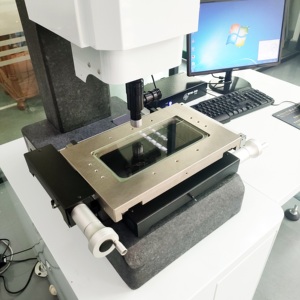

Fully Automatic Two-Dimensional Measuring Instrument Optical Image Measuring Instrument Video Measuring Instrument

Dimension Testing Machine Cnc Cmm Coordinate Measuring Machine Cnc Cmm

The realm of precision engineering and quality control has been revolutionized by the advent of 3D measurement machines. These sophisticated devices, also known as 3D coordinate measuring machines (CMM), offer unparalleled accuracy in capturing the dimensions and spatial relationships of objects in three-dimensional space. Utilized across various industries, from automotive to aerospace, these machines are integral in ensuring products meet stringent specifications.

There is a diverse array of 3D CMM machines catering to different requirements. The laser 3D measuring device is sought after for its non-contact precision, while the scanning CMM is prized for its ability to rapidly assess complex geometries. Applications range from reverse engineering to assembly analysis, where the minutest deviations are critical. The three dimensional measuring machine has become a staple in quality assurance processes.

3D measuring equipment is designed with features that ensure reliability and accuracy. Constructed from materials that resist thermal expansion and electromagnetic interference, these machines maintain their precision under various conditions. The integration of advanced sensors and software allows for detailed analysis and reporting, making the 3D measuring instrument a critical tool for engineers and technicians.

Incorporating a 3D CMM machine into the manufacturing process offers numerous advantages. The ability to quickly measure and validate prototypes speeds up development cycles. For production, these machines ensure that every part meets the required tolerances, reducing waste and increasing efficiency. In maintenance, wear and deformation can be tracked, predicting failures before they occur.

Selecting the appropriate 3D measurement machine depends on the specific needs of the task. For intricate components, a micro hite 3D or zeiss 3D measuring machine might be most suitable. For larger items, the atos scanbox offers a spacious environment for comprehensive scanning. It's essential to consider the size, complexity, and material of the objects to be measured when choosing the right equipment.

The 3D measurement machine category encompasses a broad range of devices designed to meet the exacting standards of modern industry. With the ability to capture precise measurements in three dimensions, these machines are indispensable in a variety of settings. While Alibaba.com serves as a platform to connect buyers with a multitude of suppliers offering these advanced measuring solutions, it is crucial to assess the specific measurement needs and applications to ensure the selection of the most appropriate 3D measuring instrument for your requirements.