Popular in your industry

Top categories

About 2 tons sling belt

Understanding the 2 Tons Sling Belt

Lifting slings are essential tools in material handling operations, and the 2 tons sling belt is a category that stands out for its specific load-bearing capacity. These belts are designed to handle weights up to 2 tons and are integral in various industries for safe and efficient load management. This introduction delves into the different aspects of these sling belts, from their types to their applications and features.

Types of 2 Tons Lifting Slings

The market offers several types of lifting slings capable of supporting 2-ton loads, each with unique characteristics. The selection includes round slings, chain slings, web slings, and more. Round slings are known for their flexibility and grip, chain slings for their durability and high-temperature resistance, and web slings for their versatility and ease of use. Each type serves a specific purpose and is chosen based on the nature of the load and the lifting environment.

Applications and Features

The 2 tons sling belt is versatile, finding applications in construction, manufacturing, logistics, and more. These slings are designed for repeated use and are made from materials that ensure longevity and reliability. Features such as adjustable lengths, protective sleeves, and various hook options enhance their functionality. When selecting a sling, it is crucial to consider the shape, size, and material of the load to ensure a secure lift.

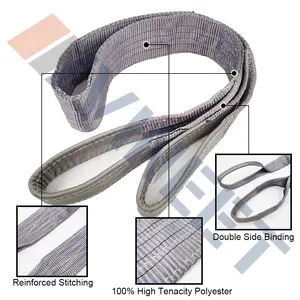

Material Composition and Advantages

Materials used in the construction of 2 tons lifting slings include high-strength fibers, steel, and engineered polymers. These materials are chosen for their strength-to-weight ratios and resistance to environmental factors like abrasion, UV exposure, and chemicals. The advantages of using the correct sling material include improved safety, reduced risk of damage to the load, and increased efficiency in lifting operations.

Choosing the Right 2 Tons Sling Belt

Selecting the appropriate 2 tons sling belt requires an understanding of the load's weight, the frequency of lifts, and the lifting environment. Factors such as humidity, temperature, and potential exposure to corrosive substances must be considered to ensure the sling's durability and performance. Proper sling configuration is also vital for maintaining load balance and ensuring the safety of both the load and the lifting equipment.

Ensuring Safe Operation

Safety is paramount when operating with heavy-duty lifting slings. It is essential to adhere to operational guidelines and regularly inspect the slings for wear and tear. Users should be trained in the correct usage and maintenance of these slings to prevent accidents and prolong the life of the equipment.