(2736 products available)

There are different types of 12v explosion-proof lights. Here is a summary of the most popular options:

12V LED Work Light

These lights are known for their high energy efficiency and long lifespan. They are usually used in hazardous areas like oil and gas fields, mining, and chemical plants.

12V LED Light Bar

These lights come in different sizes and power ratings. They are versatile and can be used for various applications in off-road lighting, mining, and industrial settings.

12V LED Flood Lights

These lights are popular for their brightness and low power consumption. They are commonly used in outdoor areas like petrochemical facilities, parking lots, and building perimeters.

12V LED High Bay Light

These lights are specifically designed for high ceilings and large areas. They provide uniform lighting and are mostly used in warehouses, factories, and industrial facilities.

12V LED Explosion Proof Light Fixture

These lights are specifically designed for indoor lighting. They are ideal for areas with flammable gases and dust particles. The fixtures provide reliable lighting for industrial operations.

12V Portable LED Light

These lights can be moved from one place to another. They are versatile and commonly used in remote worksites, emergency response, and temporary lighting solutions.

12V LED Hazardous Location Light

These lights are designed for specific hazardous locations. They comply with different safety standards and provide reliable lighting in environments with potential explosion risks.

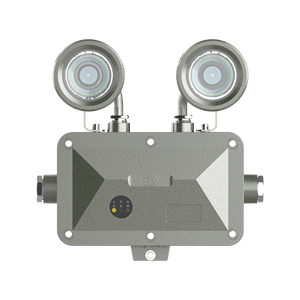

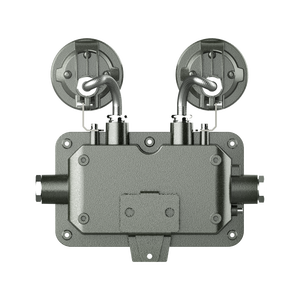

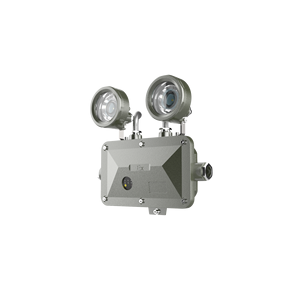

12V LED Emergency Lighting

These lights are important in evacuation procedures and emergency situations. They are designed to provide illumination in an emergency power-off scenario.

12V LED Task Lighting

These lights are designed to provide bright and focused illumination. They are commonly used in industrial workstations, maintenance areas, and assembly lines.

Explosion proof 12v lights are specifically designed to prevent the ignition of hazardous materials in environments where flammable gases, vapors, or dust are present. Here are some of the key features and functions of these lights:

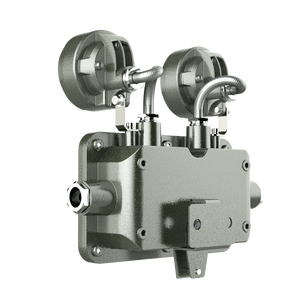

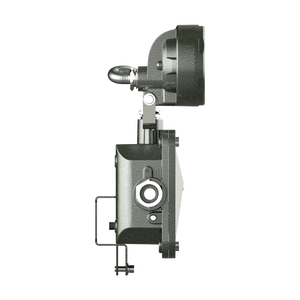

Housing and Material:

The housing is usually made from materials like aluminum, which are non-sparking and can withstand high impacts. This makes them durable and resistant to corrosion. The housings are typically sealed to prevent the ingress of dust, moisture, and other contaminants.

Sealing and Gasketing:

The lights are carefully sealed with gaskets to create a barrier. This prevents the entry of explosive dust or vapors into the light and causes sparks. The sealing is done using high-quality materials that can withstand extreme temperatures.

Tempered Glass Lenses:

The lights come with tempered glass lenses. This glass is usually thick and strong to prevent breakage. The glass is transparent to allow maximum light output. They also have special coatings on the inner side of the glass to reduce glare.

Electrical Components:

These lights use explosion-proof electrical components. For example, switches, connectors, and circuit boards. They are specifically designed to operate in hazardous environments. The electrical components are enclosed in a housing. This prevents any sparks from escaping and igniting flammable gases or dust.

Pressure Relief Vents:

Some explosion-proof lights have pressure relief vents. These vents are used to release any built-up pressure in case of an internal explosion. This helps to prevent the housing from bursting. The vents help to maintain the integrity of the light.

Junction Boxes:

Explosion proof lights may include junction boxes. These are used to connect and protect electrical wiring. They provide a safe enclosure for wire connections. Junction boxes help to prevent sparks and protect the wiring from damage and dust.

Certification and Compliance:

12v explosion proof lights are designed as per strict industry standards. For example, ATEX, IECEx, and NEC. They are regularly tested and certified by authorized organizations. Compliance with these standards ensures the safety and reliability of the lights in hazardous locations.

LED Technology:

Most of these lights use LED technology. LEDs consume less power and have a longer lifespan. They also produce less heat. Lowering the risk of ignition in explosive environments. Additionally, LED lights have a high lumen output. This ensures adequate illumination in dark areas.

There are several application scenarios for 12v explosion-proof lights. These are:

Mining

Explosion-proof lights are used in mining to provide adequate lighting in areas with flammable gases and dust. The lights are designed to prevent sparks that may cause explosions. They are used in underground mines and open-pit mining.

Oil and gas industry

Explosion-proof lights are used in drilling rigs, refineries, and storage facilities. The lights are used in areas with flammable gases, vapors, and liquids. They provide adequate lighting for workers to carry out their tasks safely.

Aviation

Explosion-proof lighting is used in aircraft and airports. The lights are used in areas with flammable liquids, vapors, and gases. They are also used in fuel storage and dispensing areas to prevent sparks that may cause an explosion.

Manufacturing

12V explosion-proof lights are used in factories that handle combustible dust or flammable liquids and gases. The lights are used to illuminate production areas, storage facilities, and shipping bays.

Chemical plants

Explosion-proof lights are used in chemical plants that manufacture or handle flammable chemicals. The lights are installed in processing areas, storage tanks, and loading docks.

Marine

These lights are used in ships and offshore platforms. They are used in areas with flammable liquids, vapors, and gases. The lights are also used in storage facilities and fuel dispensing areas.

Emergency lighting

12v explosion-proof emergency lights are used in evacuation routes, emergency exits, and backup power systems. They provide illumination during emergencies in hazardous environments.

Temporary lighting

They can be used as temporary lighting in hazardous locations during construction or maintenance. The lights are easy to install and relocate when required.

Outdoor lighting

These lights can be used to illuminate outdoor areas in hazardous environments. They can be installed in parking lots, walkways, and storage areas.

Choosing the right 12v explosion-proof light requires careful consideration of various factors to ensure safety, compliance, and suitability for the intended application. Here are some key factors to consider when choosing:

Assess the Hazardous Area

Identify the type of explosive materials that will be present, such as gases, vapors, or dust. Determine the zone classification based on the likelihood of explosive atmospheres, such as Zone 0, 1, or 2 for gas, and Zone 20, 21, or 22 for dust. Consider the ventilation of the area and the temperature of the light fixtures.

Compliance and Certification

Look for lights that meet international standards for safety in hazardous areas, such as ATEX, IECEx, UL, and C1D1 for certifications and markings. Ensure that the lights are suitable for the specific zone classification and gas or dust groups.

Material and Build Quality

Choose lights with durable materials that can withstand harsh conditions, such as aluminum, stainless steel, or reinforced polymer. Look for features like impact resistance, corrosion resistance, and high-temperature resistance. Consider the build quality, such as sealed construction and reinforced lenses.

Lighting Requirements

Determine the required brightness level, measured in lumens, for the specific application. Consider the color temperature, whether a warm or cool light is needed. Assess the beam angle and direction, and choose lights with the desired lighting distribution.

Power Source and Efficiency

Ensure that the 12v lights are compatible with the available power supply, such as batteries, solar panels, or 12v transformers. Look for energy-efficient options, such as LED lights, to reduce power consumption and increase luminosity. Consider the light's operating costs and energy efficiency ratings.

Maintenance and Lifespan

Consider the maintenance requirements of the lights, such as cleaning and replacement of parts. Choose lights with a long lifespan to reduce replacement frequency and costs. Look for features that facilitate maintenance, such as modular design and easy access points.

Installation and Compatibility

Ensure that the explosion-proof lights are compatible with the existing infrastructure, such as mounting options, wiring, and controls. Consider the installation process, and choose lights that are easy to install and require minimal modifications.

Q1: What is the main purpose of an explosion-proof light?

A1: These lights are designed to provide illumination in hazardous locations. They prevent sparks or flames from igniting explosive gases, vapors, or dust in the environments.

Q2: What does explosion proof light mean?

A2: An explosion-proof light means it has a durable construction. This can be glass or aluminum that encases the internal components. They can withstand pressure in case of an explosion. For example, in the areas where they are used, the light can be able to contain an explosion.

Q3: Do LED lights work on batteries?

A3: Yes, some LED lights can work with batteries. For instance, 12v explosion proof LED lights can be powered by batteries. They are commonly used in portable or temporary lighting solutions.

Q4: What is the difference between LED and fluorescent lights?

A4: LED lights have a much longer lifespan than fluorescent lights. They also offer better life efficiency and durability. Unlike the fluorescent light, LED lights do not have any harmful gases.