When selecting materials for shell and tube heat exchangers, thermal efficiency and cost are pivotal considerations. Materials like copper and copper alloys are known for excellent thermal conductivity, essential for effective heat transfer. However, alternatives such as carbon steel, stainless steel, and higher alloys, while slightly less efficient, offer a balance of performance and cost.

The price and availability of materials are subject to market fluctuations, impacting the overall cost of the heat exchanger. Alloys with a higher content of corrosion-resistant metals tend to be more expensive due to their superior mechanical properties and corrosion resistance. Conversely, materials like carbon steel are more affordable but may not offer the same level of corrosion resistance or durability.

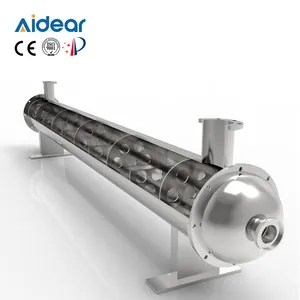

In terms of design, the shell and tube sides of the exchanger can be constructed from different materials, optimizing both cost and performance. Utilizing a more corrosion-resistant alloy for the tube side, which typically involves contact with the product, and a less expensive material for the shell side can be cost-effective. Additionally, the choice between seamless and welded tubes can significantly affect the price, with seamless options being more costly.

Suppliers and fabricators play a role in material selection, as not all have the capabilities to work with certain high-performance alloys. The number of suppliers for a given material can influence both cost and lead time. For instance, common materials like carbon steel and stainless steel are widely available, leading to competitive pricing and shorter lead times compared to specialized materials like high-grade alloys, which require controlled environments for fabrication.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4