hama plastic flame resistant is divided according to its reaction to heat, synthesis, and composition. When it comes to the reaction to heat, these raw materials are divided into either thermosets or thermoplastics. When thermoplastics are at room temperature or an average temperature, they can be distorted. When heated to a higher temperature, it becomes liquid. If exposed to frigid temperatures long enough, it will harden again. Examples of thermoplastics include rubber, polyethylene, cellulosic, and nylon. On the other hand, thermosetting plastics are heated, fused, and hardened. hama plastic flame resistant cannot be remelted once it has gone through this procedure. Examples include epoxy and amino resins, phenol polymers, and polyesters. There are various ways of working with a hama plastic flame resistant irrespective of the type. These ways include extrusion, blow molding, rotational molding, and injection molding.

Each hama plastic flame resistant has its use. Polypropylene is particularly prevalent in interior automobile applications. However, polyamide is more prevalent in the engine compartment because it has a greater melting temperature and is stronger. ABS is another hama plastic flame resistant that we come across in our daily lives. It is used for making kitchen appliances and computer equipment because of its impact resistance and hardness. It is also used in the automobile industry if a high-gloss finish and the necessary qualities of heat resistance are required. Some manufacturers also prefer mixing the two raw materials to benefit from both of their properties.

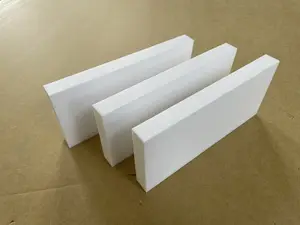

For a wholesale hama plastic flame resistant, visit Alibaba.com. This online shopping platform has partnered with various Chinese wholesalers to offer you a wide range of plastic raw materials. Visit the website at any time and place your order with a few clicks.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4