Automated Fish Sorting Equipment Explained

Automated fish sorting equipment is a significant advancement in the seafood industry, particularly beneficial for commercial operations requiring efficient and accurate fish grading and sorting. These systems are designed to classify fish based on predetermined criteria like species, size, and quality, thereby reducing labor costs and enhancing operational efficiency.

The primary users of automated fish sorting equipment are large-scale fish farms, fish processing plants, and seafood wholesalers dealing with high volumes. These systems play a crucial role in ensuring that seafood products meet specific standards and regulations related to size, quality, and species composition.

Utilizing technologies such as machine learning, computer vision, and at times robotics, these automated systems scan each fish individually as it passes through, employing algorithms to classify them accurately. This technological approach enables precise and rapid sorting, surpassing the capabilities of manual methods. Consequently, it not only speeds up the grading process but also reduces human error while maintaining consistent quality control.

Customizable to accommodate various fish species and sizes, automated fish sorting equipment proves versatile for different applications. Moreover, they can be integrated into larger systems encompassing functions like counting, weighing, and packing, providing comprehensive solutions for fish processing requirements.

Varieties of Automated Fish Sorting Equipment

Automated fish sorting equipment is available in diverse forms to address various industry needs. Some common types include:

-

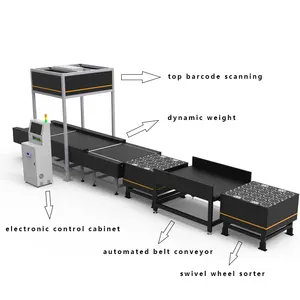

Weight Grading Systems: These systems categorize fish based on their weight, essential for determining selling prices and managing inventory in commercial settings like supermarkets or fish markets.

-

Size Grading Systems: Sorting fish by length or width, this type is valuable for species where size significantly influences quality, such as tuna or swordfish in specialized fisheries.

-

Color Sorting Systems: Using optical sensors, these machines sort fish by color, effective for separating different species or grades based on color attributes correlated with taste or texture.

-

Shape Sorting Systems: Focusing on fish contours, these systems differentiate between species or cuts, commonly used in processing plants with specific fish shape requirements for recipes or consumer preferences.

-

Conveyor Belt Scales: Equipped with weight sensors, these scales weigh fish as they move along the belt, suitable for continuous operations such as canning or freezing processes.

Choosing the Right Automated Fish Sorting Equipment

Selection of suitable automated fish sorting equipment is vital for businesses handling large seafood volumes. The chosen equipment should align with operational needs, fish characteristics, and desired outcomes.

Considering the scale of operation is crucial. Larger operations may benefit from advanced sorting systems with multiple conveyor lines and sophisticated software for complex sorting tasks, while smaller operations could find simpler systems based on single criteria like size or weight more cost-effective.

Additionally, the nature of the fish being sorted is a key consideration. Delicate species may require gentle handling to prevent damage, while robust species may be processed more swiftly.

Efficiency is another critical aspect to contemplate, with machinery designed for high productivity in terms of sorting speed and throughput volume, directly impacting operational costs and efficiency.

Lastly, post-sales service is essential. Reliable technical support and maintenance services ensure uninterrupted operations in case of equipment issues.

Alibaba.com's Automated Fish Sorting Equipment Selection

Alibaba.com serves as a premier marketplace for sourcing tailored automated fish sorting equipment to meet the fishing industry's unique needs. With a wide array from global suppliers, Alibaba.com simplifies procurement by offering various automated solutions for different fish processing operations. The platform's comprehensive filtering system allows businesses to refine their choices based on specifications like material construction, core components, service location, and after-sales support options.

Alibaba.com's commitment to facilitating global trade is evident through user-friendly features, multilingual support, order services, and Trade Assurance for secure transactions until delivery completion. For businesses seeking reliable automated fish sorting solutions globally, Alibaba.com provides a platform to engage with verified suppliers offering diverse options to enhance operational efficiency.

Whether sorting diverse fish types or optimizing large-scale fish processing lines, Alibaba.com ensures businesses find the right solutions without compromising quality or performance, establishing itself as a go-to resource for sourcing commercial equipment like Automated Fish Sorting Machines.

FAQs on Automated Fish Sorting Equipment

What is Automated Fish Sorting Equipment?

Automated Fish Sorting Equipment utilizes technologies like cameras, sensors, and computers to sort fish based on criteria such as size, weight, and quality. It streamlines fish separation, particularly beneficial in high-volume fishing and processing environments.

How does Automated Fish Sorting Equipment operate?

Automated Fish Sorting Equipment functions by employing cameras, sensors, and sometimes air jets or electrical paddles to sort fish based on size, weight, and color criteria, facilitating accurate sorting decisions.

Which businesses commonly utilize Automated Fish Sorting Equipment?

Restaurants, seafood markets, food processing plants, and fish farms are among the businesses that commonly employ Automated Fish Sorting Equipment. These systems are essential for industries requiring rapid and consistent fish sorting.

What considerations are important when choosing the material for Automated Fish Sorting Equipment?

When selecting material for Automated Fish Sorting Equipment, factors such as the fish type, operating environment, and durability requirements should be considered. Stainless steel is often preferred for its durability and ease of cleaning in food processing applications.

Does Automated Fish Sorting Equipment come with after-sales support?

After-sales support availability varies by supplier. It is advisable to inquire about the support provided, including online assistance, video support, and overseas machinery servicing by engineers, before making a purchase.

Can Automated Fish Sorting Equipment handle various fish species?

Many Automated Fish Sorting Equipment systems are designed to accommodate a range of species using programmable software that can adapt to different fish shapes and sizes.

What maintenance requirements are specific to Automated Fish Sorting Equipment?

Maintenance for Automated Fish Sorting Equipment typically involves regular inspections for wear, cleaning of sensors and cameras, and ensuring up-to-date software. Suppliers may provide detailed maintenance guidelines for the equipment.

How can I determine the suitable size for Automated Fish Sorting Equipment for my business?

To determine the right size for Automated Fish Sorting Equipment, consider factors like fish processing volume, facility space, and throughput requirements. Suppliers can offer guidance on selecting the appropriate size based on these criteria.

What features should I prioritize in Automated Fish Sorting Equipment for my business?

Key features to seek in Automated Fish Sorting Equipment include efficient fish sorting, user-friendly operation, safety components like emergency stop buttons, and durability to withstand continuous industrial use.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4