Understanding the 100t Cooling Tower

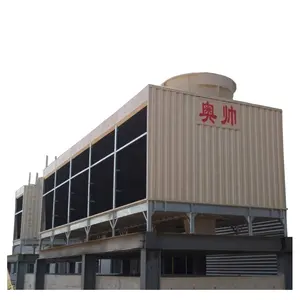

A 100t cooling tower is an industrial equipment designed to remove heat from water by bringing it into direct contact with air. This process cools the water, making it suitable for reuse in various industrial applications. The '100t' denotes the cooling capacity of the tower, which can handle 100 tons of heat removal per hour.

Components and Functionality

The efficiency of a 100t cooling tower hinges on its components. Key parts include cooling tower fill, which facilitates heat transfer by maximizing water and air contact, and cooling tower fans, which drive the air flow necessary for the heat exchange process. The cooling tower spray nozzles play a pivotal role in dispersing water over the fill, while cooling tower basins collect the cooled water for recirculation.

Types of 100t Cooling Towers

There are several types of cooling towers, each with unique features. The crossflow cooling tower allows air to move horizontally across the flow of falling water. In contrast, the counterflow cooling tower has air moving vertically upward against the descending water. The hyperbolic cooling tower, recognized by its distinctive shape, is engineered for large-scale operations and is known for its natural draft capabilities.

Applications and Advantages

The industrial cooling tower is versatile, serving sectors from manufacturing to power generation. Its benefits include a significant reduction in water consumption compared to once-through cooling systems and the ability to maintain optimal temperatures for industrial processes. The 100t cooling tower model is particularly suited for medium-sized operations seeking efficient thermal management.

Materials and Maintenance

Materials used in the construction of a cooling tower for industrial use include corrosion-resistant metals, plastics, and composites, ensuring longevity and reliability. Regular maintenance of the cooling tower components is crucial for sustained performance, involving inspection of the fill, nozzles, fans, and basins.

Choosing the Right 100t Cooling Tower

Selecting the appropriate 100t cooling tower requires an understanding of specific industrial needs and environmental conditions. While Alibaba.com does not endorse any particular brand or make claims about product quality, the platform offers a diverse array of options to cater to various requirements in the field of thermal management.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4